- Generality

- Reagent Availability

- Experimental User Friendliness

- Criteria #4

- Criteria #5

-

General Characteristics

The original Julia olefination procedure was somewhat inconvenient as it required three operations (nucleophilic addition, acetylation, and elimination using toxic Na amalgam).

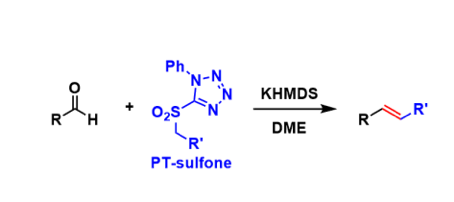

A modified single-step method was developed later by fine-tuning the aromatic sulfone moiety, although the control of E/Z selectivity remained unsolved. Kocienski developed a further improved version using PT(phenyltetrazole)-sulfone (the Julia-Kocienski olefination). This reaction gives olefin products with high E-selectivity.

-

General References

- Baudin, J. B.; Hareau, G.; Julia, S. A.; Ruel, O. Tetrahedron Lett. 1991, 32, 1175. doi:10.1016/S0040-4039(00)92037-9

- Blakemore, P. R.; Cole, W. J.; Kocienski, P. J.; Morley, A. Synlett 1998, 26. doi:10.1055/s-1998-1570

- Kocienski, P. J.; Bell, A.; Blakemore, P. R. Synlett 2000, 365. DOI: 10.1055/s-2000-6536

<Reviews>

- Blakemore, P. R. JCS Perkin Trans. 1 2002, 2563. doi: 10.1039/b208078h

- Aissa, C. Eur. J. Org. Chem. 2009, 1831. DOI: 10.1002/ejoc.200801117

- Zajc, B.; Kumar, R. Synthesis 2010, 1822. DOI: 10.1055/s-0029-1218789

- Chatterjee, B.; Bera, S.; Mondal, D. Tetrahedron: Asymmetry 2014, 25, 1. doi:10.1016/j.tetasy.2013.09.027

- Pfund, R.; Lequeux, T.; Gueyrard, D. Synthesis 2015, 47, 1534. DOI: 10.1055/s-0034-1380548

-

Reaction Mechanism

The mechanism involves intramolecular attack of the alkoxide intermediate to the tetrazole ring and elimination (the Smiles rearrangement).

-

Examples

An application to the synthesis of ent-lepadin F.

The modified sulfone reagent provides a practical way to methylenate carbonyl compounds.[1]

The synthesis of (+)-ambruticin.[2]

The synthesis of fluorinated alkenes.[3]

-

Experimental Procedure

A typical experimental procedure for the Julia-Kocienski olefination.[4]

To a stirred solution of the PT-sulfone (2.80 g, 10.0 mmol) in anhydrous DME (40 mL) under nitrogen at -55°C was added dropwise via cannula a solution of potassium hexamethyldisilazide (2.74 g, 80% by weight, 11.0 mmol) in DME (20 mL) over 10 min. The yellow-orange solution was stirred for 70 min during which time the solution became dark brown. Neat cyclohexanecarboxaldehyde (1.67 g, 15.0 mmol) was added dropwise over 5 min. and the mixture stirred at -55°C for 1h during which time the colour changed to light yellow. The cooling bath was removed and the mixture stirred at ambient temperature overnight whereupon H2O (5 mL) was added and stirring continued for 1 h. The mixture was diluted with Et2O (150 mL) and then washed with H2O (200 mL). The aqueous phase was extracted with Et2O (3 x 30 mL) and the combined organic layeres washed with H2O (3 x 50 mL) and brine (50 mL). After drying over MgSO4, the solvent was removed in vacuo to yield a pale yellow oil (2.74 g) which was purified by column chromatography (SiO2, hexanes) to give the desired alkene (1.18 g, 7.1 mmol, 71%) as a colourless oil after kugelrohr distillation (bp 180°C/15 mmHg).

-

Experimental Tips

-

References

- (a) Ando, K.; Kobayashi, T.; Uchida, N. Org. Lett. 2015, 17, 2554. DOI: 10.1021/acs.orglett.5b01049 (b) Aissa, C. J. Org. Chem. 2006, 71, 360. DOI: 10.1021/jo051693a

- Liu, P.; Jacobsen, E. N. J. Am. Chem. Soc. 2001, 123, 10772. DOI: 10.1021/ja016893s

- Zhao, Y.; Huang, W.; Zhu, L.; Hu, J. Org. Lett. 2010, 12, 1444. DOI: 10.1021/ol100090r

- Blakemore, P, R.; Cole, W. J.; Kocienski, P. J.; Morley, A. Synlett 1998, 26. doi:10.1055/s-1998-1570

-

Related Reactions

-

Related Books

[amazonjs asin=”352730634X” locale=”US” title=”Modern Carbonyl Olefination: Methods and Applications”]

-

External Links

- Julia Olefination (Wikipedia)

- Overview of Julia-Kocienski Olefination (by D. A. Evans Group: PDF)

- Julia-Lythgoe Olefination (organic-chemistry.org)

- Modified Julia-Kocienski Olefination (organic-chemistry.org)